Cardboard Box Printing | Diverse and Custom Models | Best Quality

Cardboard box printing is one of the most widely used packaging solutions that, due to its unique design and structure, is used in various industries. Various types of cardboard boxes in models such as keyboard boxes, sliding boxes (matchbox style), pillow boxes, and packaging boxes with dividers, provide diverse and practical packaging solutions for different products. These boxes with exclusive printing and custom design, in addition to maintaining product quality and safety, help in product introduction, desire to keep the box at work and home, branding, and attracting customer attention. The notable advantages of cardboard boxes include light weight, easy portability, and optimal use of space. Moreover, cardboard packaging with recyclability is considered an environmentally friendly option and helps reduce waste.

The use of cardboard boxes in product packaging, given their flexibility and reasonable cost, has led many businesses to turn to using these types of boxes. Among the applications of this product in industries are for cosmetics and hygiene products packaging printing, beverage packaging printing, various food products such as confectionery box printing, nuts box printing, Sohan box printing, as well as for pharmaceutical box printing, home appliance packaging carton printing, tissue box printing and ... they have very good applications and can be designed and printed in different sizes.

Cardboard Box Order and Printing

Cardboard box order and printing must be done with the aim of protecting the product with original quality and delivering the product to the end consumer. Each product, depending on its material, structure, and transportation conditions, needs its own specific packaging to protect it in the best way while maintaining an attractive appearance from initial presentation until use by customers. Various types of cardboard box printing and custom packaging printing in our company are designed to cover all your needs. We produce packaging that is precisely tailored to your product's dimensions, shape, and characteristics, and with creative designs aligned with brand identity, make it stand out in the market. Our cardboard box printing services include selecting suitable and quality materials, graphic design, and various modern printing techniques that allow you to fully customize your desired packaging. From small cardboard boxes to large industrial carton making, we produce high-quality packaging with precision that not only protects your product well but also creates a distinct visual experience for customers.

Cardboard Packaging Box Printing

Cardboard packaging printing is highly popular among brands and manufacturers due to its special characteristics. Cardboard packaging is produced from environmentally friendly materials and is easily recyclable. This type of packaging, in addition to protecting the product, allows for custom printing, so that necessary information and attractive designs can be implemented on it. Cardboard box printing is done through various methods such as offset printing, digital, and silk screen printing, each having its own unique advantages.

Box and packaging printing in cardboard not only has the duty of protecting the product but also has a significant impact on branding and brand awareness among target audiences by presenting an attractive appearance. The right choice of design, color, and type of printing can help distinguish the brand in the market and attract customer attention.

One of the solutions used for completing, making attractive, and in some cases for branding packaging boxes is adhesive label printing. Adhesive labels have many uses and advantages in packaging, which we have fully explained and introduced their types on this product's page.

Cardboard Box Design and Printing

High-quality cardboard box design and printing are made from glossy cardboard or innerboard that have a smooth and durable texture and enable quality color printing. Since each product needs its own specific packaging, cardboard boxes are produced in various designs and sizes, with high customization capability to highlight the unique features of each brand. For designing and printing ideal boxes, attention to design details and post-printing services such as printing type and coating type is of high importance to both give the product an attractive appearance and protect it against external damage.

Cardboard box design and printing with exclusive designs is possible in high circulation printing in high circulation makes cardboard packaging an efficient and economical choice that increases brand attractiveness and customer satisfaction. These designs are done using graphic software such as Adobe photoshop, Adobe Illustrator, etc.

Types of Cardboard Boxes

Keyboard Box

This box, with its simple design and easy closing mechanism, is a suitable choice for packaging products that need quick and easy handling.

Base and Lid Box | Shirt Box

A box with two separate parts that, due to its high durability and elegant appearance, is suitable for luxury products and special gifts.

Sliding Box | Match Box

With its sliding mechanism and compact design, this box not only protects the product but can also be reused multiple times.

Bag-Style Box

This box's design resembles a bag, making it easier to carry and handle, ideal for light and small products.

Cardboard Banderole

This type of packaging is very suitable for quick packaging and protection of small and sensitive products, such as bottles and tubes.

Packaging Box with Hanger

With its hanging capability, this box is the best choice for displaying products in stores and creating easy access to them.

Packaging Box with Divider

A box with dividing sections designed for organizing and protecting multi-piece products, such as glasses and containers.

Cardboard Packaging Printing Costs

The final cost of cardboard packaging varies depending on the type of finishing services such as spot UV, embossing, and hot foil stamping, etc. These finishing services give your packaging an attractive and unique appearance while also affecting the costs.

Purchase Cardboard Packaging for Products

We offer high-quality and durable cardboard boxes in various dimensions and designs. You can choose from pre-designed or customized packaging to present your product in the best possible way. Whether you're looking for simple boxes or luxury packaging, we cover all your needs with guaranteed quality. By purchasing cardboard packaging from OJENILI, you will benefit from professional services and products with the highest standards.

Cardboard Box Printing with Advanced Technologies

In the modern packaging world, the use of advanced technologies plays a crucial role in producing high-quality and efficient cardboard box printing. These technologies not only increase printing accuracy but also create special visual effects that have turned cardboard boxes into one of the most important advertising tools for brands.

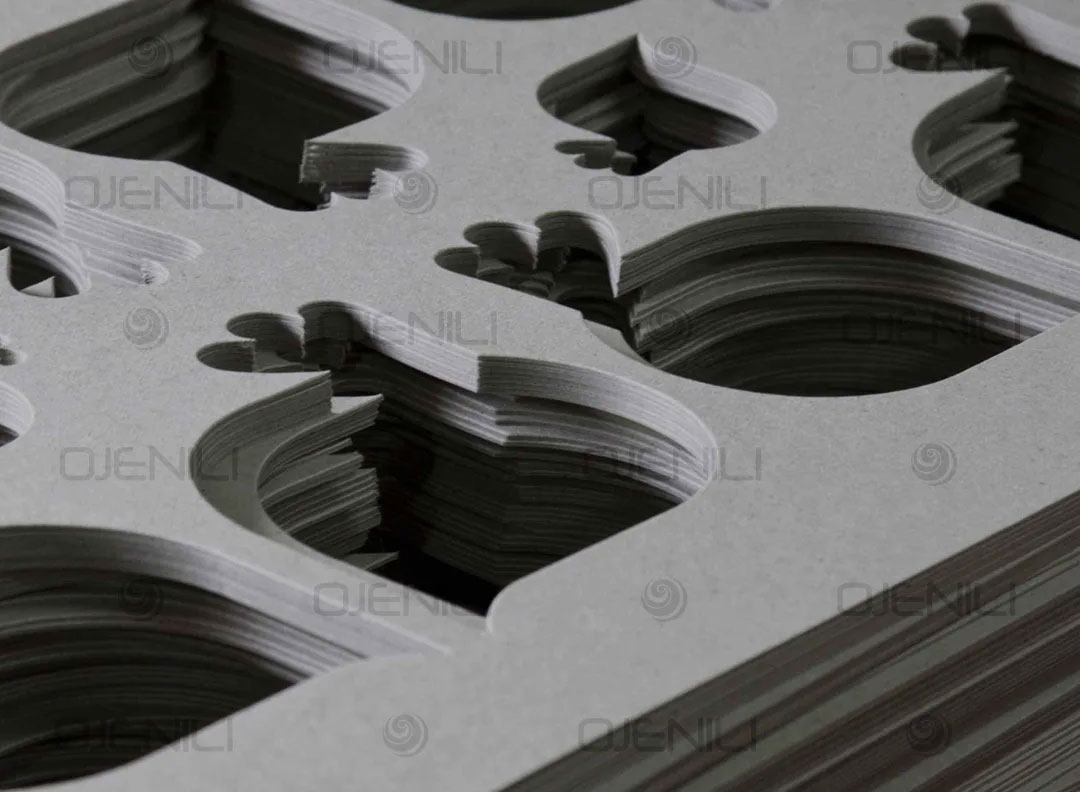

Automatic Die-cutting and Waste Removal

Automatic die-cutting technology is one of the most advanced cardboard cutting methods in the packaging industry. This process enables the production of highly precise cardboard boxes without manual intervention. Automatic waste removal helps eliminate excess cardboard edges after cutting. This feature results in the production of boxes with clean and precise edges, which is very important for packaging sensitive or valuable products.

- High Cutting Precision: Automatic die-cutting technology enables the creation of complex and precise shapes, which is particularly important in producing cardboard boxes with special and unique designs.

- High Speed and Efficiency: Using this technology, box production is completed faster, which can help reduce production costs and increase productivity.

Window Patch and Film Application Machine

One type of cardboard box is the window box or window pack. Adding a transparent window to a cardboard box is an attractive solution for displaying part of the product inside the box. The automatic window patch and film application machines enable transparent films to be attached to cardboard boxes with high precision and quality.

- Product Display: This technology allows brands to showcase their products to customers without the need to open the box. This method is particularly useful for beauty products, food items, and luxury goods.

- Product Protection: Transparent films, in addition to aesthetics, help protect the product against dust and external damage.

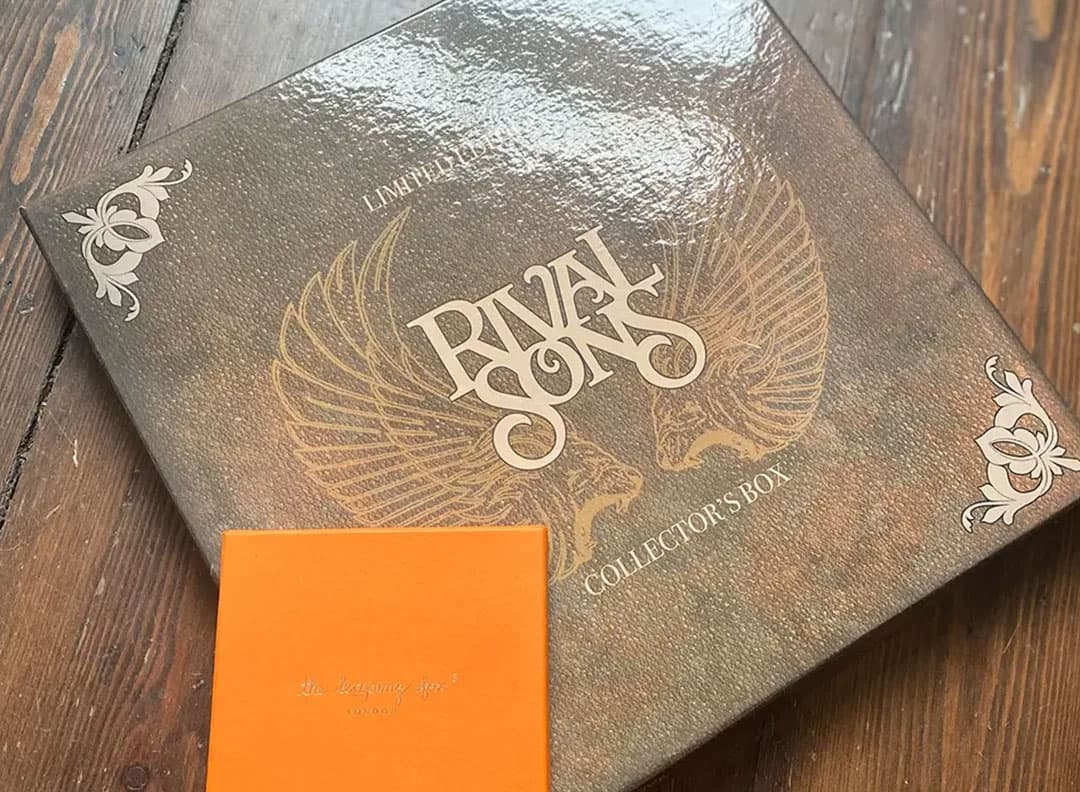

Embossing and Foil Stamping

One of the important techniques in enhancing packaging appeal is the use of embossing and foil stamping techniques. These processes help cardboard boxes appear more visually striking and professional.

- Embossing: This technique attracts customers' attention by creating raised surfaces at specific points on the box and increases the sense of product luxury.

- Foil Stamping: Using colored foils such as gold or silver on the box surface creates special and shiny effects that double the visual appeal of packaging.

Spot UV and Cellophane Wrapping

Spot UV and cellophane wrapping are other advanced techniques used to increase the durability and beauty of cardboard boxes.

- Spot UV: This process selectively coats a surface of the box with a glossy layer. Spot UV allows brands to display logos or other graphic elements more prominently and attractively.

- Lamination: Using cellophane on boxes helps protect them against moisture, scratches, and environmental damage. Also, this layer increases the useful life of cardboard boxes and improves their appearance.

Benefits of Using Advanced Technologies in Cardboard Box Production

- Increased Quality and Precision: Using modern technologies like automatic die-cutting and waste removal helps produce cardboard boxes with high precision and clean edges, which leads to improved user experience and increased customer satisfaction.

- Improved Visual Appeal: Using printing effects such as embossing techniques, foil stamping, and spot UV allow brands to design their cardboard boxes more visually attractive and professional. These features can have a positive impact on customers' purchasing decisions.

- Increased Durability and Resistance: Lamination and film application is one of the printing services that helps protect cardboard boxes and their internal products against environmental factors. These technologies are especially important for products that need long-term storage.

- Cost Savings: Using automatic machines reduces the need for human resources and increases production speed. This can help reduce production costs and increase productivity.

Applications of Cardboard Boxes in Various Industries

Cardboard boxes due to their flexible structure and diverse designs, have widespread applications in various industries including food, pharmaceutical, clothing, and consumer goods. These boxes with custom printing and customized design, in addition to safe packaging and product protection, help with branding.

Hardbox, keyboard box, and top-and-bottom boxes are used for packaging luxury products and special gifts, drawer boxes (matchbox style) and cardboard bands are used for packaging small and delicate items. The diverse applications of these products demonstrate the flexibility and high capability of cardboard boxes in responding to various needs. The use of recyclable raw materials has also made these types of boxes an environmentally friendly and cost-effective option.

The applications of folding boxes in various industries due to their flexible design and unique features include:

- Pharmaceutical Industries: Safe packaging for pills, medicines, and healthcare products with accurate information printing.

- Food Industries: Durable and hygienic packaging for food products such as chocolates, sweets, and dry foods.

- Clothing and Fashion: Shirt boxes and bag boxes for clothes and accessories.

- Gifts and Luxury Products: Using top-and-bottom boxes for special gifts and luxury items.

- Electronic Products: Organized and protective packaging for electronic gadgets with compartmentalized boxes.

- Cosmetics and Healthcare Industries: Elegant and practical packaging for cosmetic products, with pillow box design.

Cardboard boxes are one of the most popular options for packaging various products. These boxes, due to their intelligent design and foldability, enable optimal use of space and reduce transportation costs.

Benefits of Cardboard Boxes

- Easy Transportation and Handling: Cardboard boxes are easily collapsible and expandable, which makes them very suitable for transportation and handling. Additionally, they occupy minimal space in storage or during transportation.

- Simple and Efficient Design: These boxes are designed to be manufactured with minimal cost and raw materials, while maintaining high strength and durability. Their simple design enables quick and easy production.

- Optimal Space Usage: Cardboard boxes are delivered flat and level, occupying less space during storage. This is particularly useful in warehouses and commercial environments where storage space is highly important.

Cardboard Box Printing Methods

Offset Printing

Offset printing is one of the most common and highest quality methods for printing folding boxes. This method is suitable for folding boxes with complex and colorful designs due to its high accuracy in displaying details and color variety. Additionally, offset printing is very cost-effective for high volumes.

Digital Printing

Digital printing is suitable for low-volume printing and custom designs that require high speed, enabling printing different designs on each box without the need for plates, making it ideal for initial samples and urgent printing jobs.

Flexo Printing

Flexo printing is an industrial method that uses flexible plates and is used for printing on various materials such as plastic and paper. This method is popular in the packaging industry due to its high speed and reasonable cost.

Custom Cardboard Box Design

Creative and unique design on cardboard boxes can help increase brand impact. Some elements used in custom cardboard box design include:

- Use of Special and Metallic Colors: Metallic colors such as silver, gold, and bronze can give boxes a luxurious appearance and attract more attention on store shelves. These colors are particularly suitable for luxury or gift products packaging.

- Matte and Glossy Lamination: Adding laminate coating to cardboard boxes not only increases resistance and durability but also creates attractive visual effects. Matte lamination gives packaging a classic and beautiful appearance, while glossy lamination enhances colors and designs.

- Spot UV: This technique enables highlighting specific parts of the design using spot UV printing. This method is especially used for logos and key texts and gives packaging a different tactile sensation.

- Gold and Silver Foiling: These techniques are typically used to add luxurious and prominent details to folding boxes. Using gold or silver foils on specific parts of the box creates an elegant and attractive appearance.

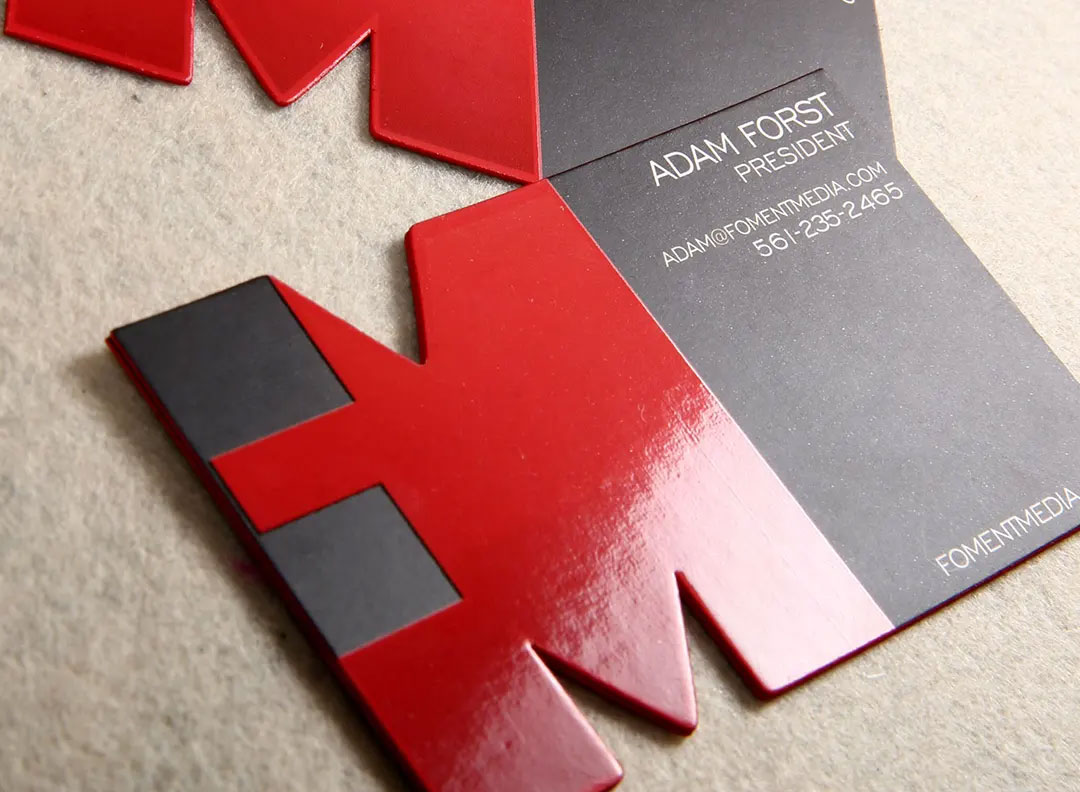

- Laser Cutting and Die-cutting: In cardboard box design, special cuts and complex die-cuts can give the box a unique shape and design. These cuts can be used as part of the design or to create windows for product display.

Attention-Grabbing and Distinction at Point of Sale

OJENILI helps brands elevate their packaging to a new level of quality and attractiveness by offering a range of finishing services in cardboard box printing and packaging. Using the most advanced equipment and modern technologies, your products will not only attract attention on shelves but will also be packaged with high precision and unique quality. Read more details on the finishing services page.

Use of Special and Metallic Colors

Metallic colors such as silver, gold, and bronze can give boxes a luxurious appearance and attract more attention on store shelves. These colors are particularly suitable for gift packaging printing and luxury products.

Matte and Glossy Lamination

Adding laminate coating to cardboard boxes not only increases resistance and durability but also creates attractive visual effects. Matte lamination gives packaging a classic and beautiful appearance, while glossy lamination enhances colors and designs. In addition to cardboard packaging, these types of services are also widely used for desk calendar printing, custom product printing, and catalog printing luxury.

Spot UV

This technique enables highlighting specific parts of the design using spot UV printing. This method is especially used for logos and key texts and gives packaging a different tactile sensation.

Gold and Silver Foil

These techniques are typically used to add luxurious and embossed details to cardboard boxes. Using gold or silver foil on specific parts of the box creates an elegant and attractive appearance.

Laser Cutting and Die-Cutting

In cardboard box design, special cuts and complex die-cuts can give the box a unique shape and design. These cuts can be used as part of the design or to create windows for product display (windowed boxes).

Custom Hologram

Custom hologram printing for packaging prevents product theft and copying. This feature is vital and used for beverage packaging printing, home appliance packaging printing, medicine packaging printing, food and agricultural products packaging printing, and more.

Cardboard Box Printing Prices and Influential Factors

The price of printing and packaging cardboard boxes depends on various factors, each of which can affect the final cost.

Factors affecting the price of printing and packaging cardboard boxes

- Box size and dimensions: The dimensions and size of the box directly affect the amount of raw materials used and the type of design and printing. Larger boxes require more cardboard and ink, therefore they will cost more.

- Type of raw materials: The choice of raw materials, such as the type of cardboard and coatings used (such as laminate, UV, etc.), can affect the cost. Higher quality cardboard and special coatings may cost more.

- Print run: The number of boxes ordered also affects the final price. Generally, as the print run increases, the cost per unit decreases as fixed costs such as plate preparation are distributed across higher volumes.

- Printing method: The choice of printing method such as offset, flexo, or digital affects the final price. Offset printing is more economical for high print runs, while digital printing is suitable for low runs and custom prints.

- Design and print complexity: Complex and multi-color designs require more time and precision and may need special techniques such as spot UV, gold foiling, or silver foiling, which can increase costs.

- Box type: The type of box, such as sliding boxes, keyboard boxes, or top-and-bottom boxes, also affects costs. Some types of boxes cost more to produce due to special cuts and die-cuts.

Order Cardboard Boxes

OJENILI is ready to meet your packaging needs by providing custom design and printing of folding boxes. For ordering and receiving consultation regarding folding box design and printing, you can call 021-42204000.

How to order:

- Share your needs with our support team via phone call or email.

- After review and consultation, the initial design of your cardboard box will be prepared.

- After final approval, the printing and packaging process will begin, and your order will be ready at the specified time.

OJENILI, your partner in enhancing the quality and attractiveness of product packaging!