Custom Laminated Carton Printing | Ordering Laminated Boxes with Desired Design and Excellent Quality

Printing Laminated Boxes and Cartons is done by applying a lamination layer on the carton as a coating, which doubles the box's strength and beauty. Laminated Box Printing at OJENILI is performed using offset printing, where complex designs and special colors in specific dimensions can be executed. These boxes are especially used for sensitive and special products such as electronic devices, cosmetics, and other luxury products.

Production and Printing of Laminated Cartons

Production of Laminated Cartons and Boxes at OJENILI is done using offset printing, with a minimum print run of 1000 pieces possible. Producing cartons with laminate coating increases the durability and visual appeal of the carton and protects the product against environmental factors like moisture, heat, and impact. Examples of products that can use Laminated Cartons for packaging include promotional products like catalogs, brochures, calendars, desktop notebooks, and point of sale advertising products such as shelf talkers, shelf stoppers, posters, self-adhesive labels, bunting, hangers, danglers, wobblers, and more.

Advantages of Laminated Cartons

The laminate coating on boxes and cartons, in addition to enhancing visual appeal, strengthens the box and protects products against environmental factors such as heat, moisture, and impact. In printing this type of packaging, the quality of color and final design is crucial; therefore, high-quality glossy paper and cellophane coating are used to stabilize colors. Choosing laminated boxes is a suitable solution for brands seeking to create a luxurious and robust image for their products.

Laminate coating is one of OJENILI's complementary services that, in addition to packaging cartons and cardboard boxes, are applied to shelf talkers, shelf stoppers, posters, and more to add to the product's advantages and increase longevity. Below, we mention several important advantages of using laminated cartons:

- Increased resistance to moisture and environmental damage: The laminate layer on the carton helps prevent moisture penetration and protects against physical damage.

- More attractive visual effects: Lamination on cartons helps increase print quality and glossiness, making the packaging appearance significantly more beautiful.

- High customization capability: These cartons can be designed and printed in various designs, colors, and dimensions, and can be personalized according to brand needs.

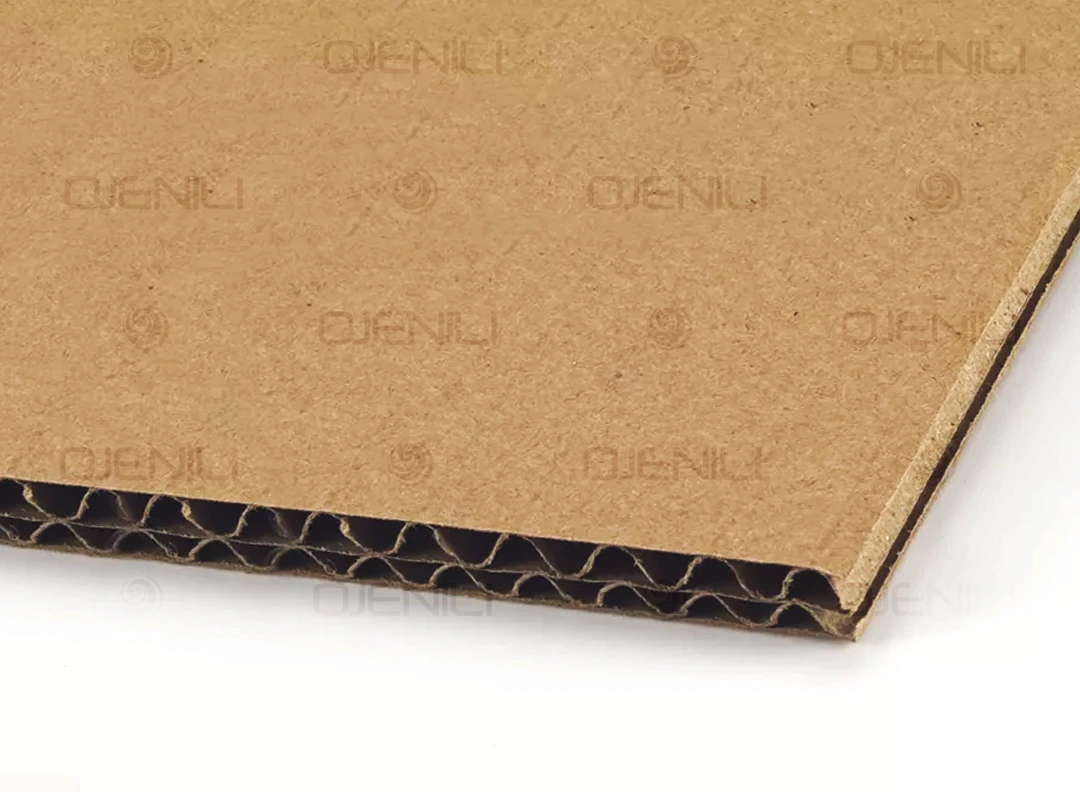

Single and Multi-layer Sheets with Various Flutes

(f, e, d, b, c, ce, cb)

In packaging, selecting the type of sheet and flute is one of the main factors determining the quality and functionality of the final product. Single and multi-layer sheets with various flutes, including f, e, d, b, c, ce, and cb, are used to create sturdy and durable packaging. These flutes act as intermediate layers in the carton structure and, with their grooves and protrusions, provide greater impact resistance and strength to the packaging.

Types of Flutes and Their Applications

- F Flute: The thinnest flute, mostly used for packaging small and delicate products like retail boxes.

- E Flute: A delicate flute suitable for lightweight products and packaging that requires precise printing.

- D and B Flutes: These flute types are used for heavier and export products that require more protection.

- C Flute: One of the most commonly used flutes that offers a good balance between resistance and flexibility.

- Composite Flutes (CE and CB): These flutes are used for boxes that need maximum strength and protection, such as industrial and export boxes.

Types of Laminated Boxes

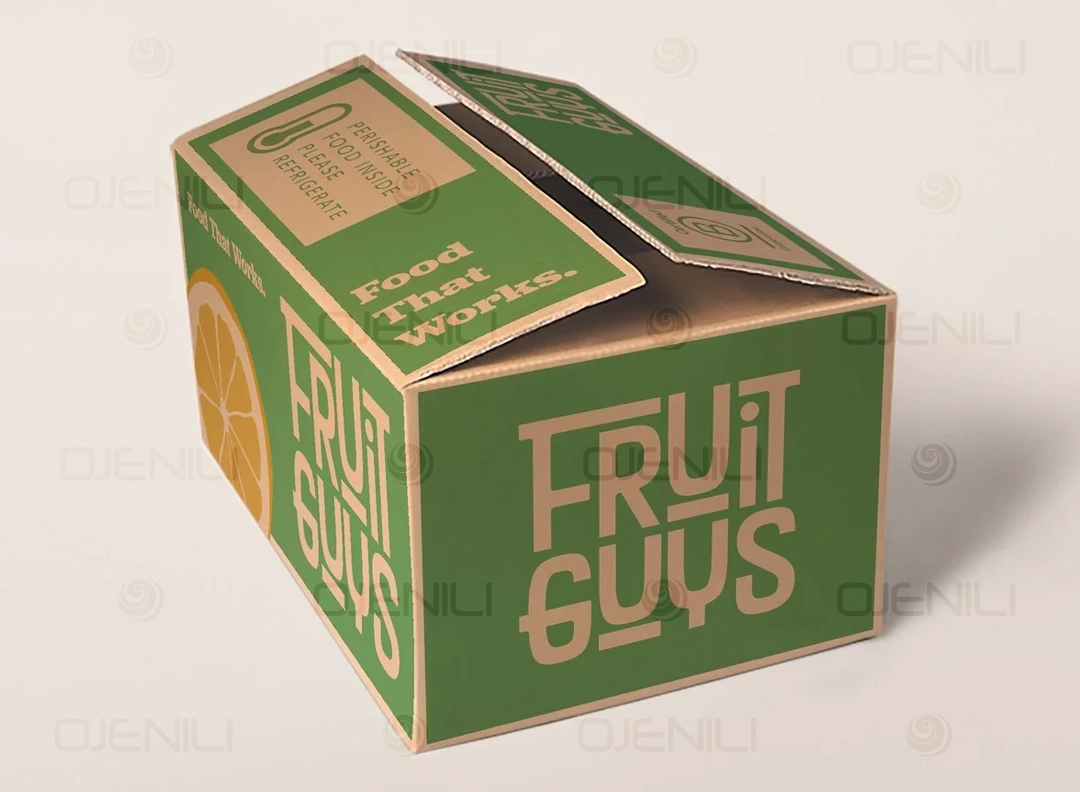

- Export Laminated Boxes: These boxes are ideal for packaging export goods such as food products, fruits, and moisture-sensitive products.

- Promotional Laminated Boxes: Suitable for luxury products that, in addition to protecting the product, enhance brand attractiveness and appeal.

- Die-cut and Special Boxes: These boxes are produced with special cuts and unique designs, used for products with specific dimensions and shapes.

Laminated Box 3 Layers (Three-Layer)

This type of box is made using three-layer cardboard sheet, which includes two paper layers and a wavy or flute layer between them. Three-layer boxes are usually used for light to medium products and, due to the laminate layer on top, have good resistance to moisture and damage

Laminated Box 5 Layers (Five-Layer)

Five-layer laminated box is made using a five-layer cardboard sheet, which includes two wavy layers between three paper layers. The five-layer structure makes these boxes more robust compared to three-layer boxes and suitable for packaging heavy or large products. The laminated layer on the box surface helps maintain its appearance and provides more resistance, also enabling high-quality printing. These types of boxes have widespread use in industrial and commercial packaging.

Laminated Cardboard Applications

Laminated cardboard application is suitable for packaging valuable and sensitive products in various industries. Cosmetics and personal care packaging, medical products and pharmaceutical packaging, beverage packaging, food product packaging, home appliance packaging and luxury products have a more prominent role. Since the laminate coating on the cardboard adds to its attractiveness, it is also widely used for packaging luxury goods and gifts, which we will name and describe the types of products below.

Food Laminated Cardboard

Can be used for food packaging such as sweets, nuts, chocolates, etc., which can also be given as gifts. This cardboard, with its laminate coating, prevents moisture infiltration, protects the product's health, and helps maintain product quality for a longer period.

Transportation Laminated Cardboard

Laminated cardboard is used for packaging and transporting products that need more protection, such as home appliance packaging. Due to its low weight and high resistance, this cardboard protects products from potential damages during transportation and handling.

Advertising Laminated Cardboard

Using laminated cardboards in point-of-sale advertising and personalized packaging like gift boxes and advertising product packaging is also common. Due to the excellent printing capability on these cardboards, they are used to create strong visual impact and attract customers. Therefore, the widespread use of laminated cardboards demonstrates the importance of this product in various high-quality and durable packaging.

Printing Price on Laminated Cardboard

Printing price on laminated cardboard depends on the cardboard and laminate quality, type and number of colors used in printing, box dimensions, and order volume, which are the most important factors determining the product's price. Generally, using high-quality glossy cardboard and laminate coating increases the box price compared to other boxes. The printing method can also affect the final cost; offset printing is one of the most common methods for printing laminated boxes and is produced in high volumes.

Overall, the laminated cardboard price is slightly higher than other cardboards; because in addition to professional printing, high-quality materials are used for its production. Contact us for laminated cardboard price inquiry.

Ordering Luxury Laminated Box Production

Ordering luxury laminated box production for packaging high-value products such as cosmetics, jewelry, and luxury goods is registered. These boxes, in addition to having an attractive appearance, have high resistance and help maintain product quality during transportation and storage. Contact us to place a laminated box order.

When purchasing laminated cardboard, you can use various custom designs such as glossy, matte, and embossed coverings. Since the printing of these boxes is usually done with offset printing machines, the print quality is very high and design details will be clearly visible. We provide specialized consultation for design and selection of the best materials to produce a box that suits your needs and preferences.

Laminated Box and Carton Production Process at OJENILI

OJENILI produces various types of laminated boxes and cartons for different industries using advanced lamination technology and modern machinery.

- Consulting and Design: Our specialists help customers choose the best structure, materials, and graphic designs for packaging.

- Printing and Lamination: Using high-quality flexo and offset printing machines, graphic designs are precisely laminated onto cartons.

- Quality Control: All production stages are carefully controlled to ensure the final product quality.

- Logistics and Shipping: After production, packaging is shipped to its destination using a reliable transportation system.

Laminated Carton Manufacturer

The mother carton is one of the most important components of industrial packaging, used for transporting products on a large scale. This type of carton is suitable for protecting goods under challenging transportation conditions due to its high strength and robust design. In industries where products are produced in large quantities and volumes, mother cartons are the best option for safe and cost-effective packaging.

Production of Export Laminated Boxes and Cartons

(Fruits and Agricultural Products)

Export packaging for agricultural products, especially fruits, is one of the key factors in sales success and maintaining product quality until the final destination. The production of laminated boxes and cartons, due to their vital role in protecting products and complying with international standards, requires high expertise and experience. In this type of packaging, factors such as resistance to pressure, humidity, temperature changes, and potential impacts during transportation are of great importance.

Importance of Export Laminated Cartons in Preserving Product Quality

One of the main concerns of exporters is maintaining product quality and freshness until delivery to foreign customers. Fruits and agricultural products, due to their high sensitivity to environmental conditions and long transportation processes, require special and robust packaging that prevents their deterioration. A suitable export laminated carton must be able to protect the product from physical damage, humidity changes, unfavorable temperatures, and even pests.

Characteristics of Export Laminated Boxes and Cartons for Agricultural Products

Export packaging, especially for fruits and vegetables, must have specific characteristics to effectively protect the product from environmental factors while also complying with international standards. Some important features of this type of packaging include:

- High Strength and Resistance: Export laminated boxes and cartons must be made from sturdy sheets to withstand the weight of products and various pressures. This strength helps reduce physical damage to products during handling.

- Moisture Resistance: During transportation to foreign countries, boxes may be exposed to moisture or rainfall. Therefore, export boxes are produced using resistant laminations and waterproof materials to prevent moisture from entering and damaging the products.

- Proper Ventilation: Many fruits need proper air circulation to maintain freshness and prevent sweating. Designing ventilation holes in boxes can help improve quality and increase product shelf life.

- International Standards: Export laminated cartons must comply with the standards of destination countries. Many countries have strict regulations regarding import packaging, use of recyclable and environmentally friendly materials, and even packaging sizes and designs.

At OJENILI, the design and production team carefully evaluates export requirements for agricultural products and designs the best packaging structures suitable for each product. From creating initial prototypes to selecting the best materials for sheets and designing prints tailored to the destination country, all stages are carried out with high precision and expertise.

Laminated Carton Design

Laminated carton design requires great precision and expertise. Choosing a suitable packaging structure directly affects product protection, transportation cost reduction, and final customer satisfaction. The design process includes a detailed examination of the product type, weight, volume, and transportation needs to ensure that packaging not only protects the product well but is also efficient throughout transportation. For this reason, all customer needs and operational challenges are considered from design to production.

Importance of Designing Laminated Cartons Suitable for Product Type

Each product has its specific packaging needs. Lightweight products require less protection, while heavier products need more robust structures to resist pressure and impact. Sensitive products like electronic goods or food items require packaging that can resist moisture, heat, or light. The specialized design team at OJENILI examines all these aspects to design the best laminated carton structure for your product.

Consulting on Choosing the Best Sheet Material

One of the most important aspects of packaging design is selecting the appropriate material. Each type of packaging sheet has unique characteristics that play a key role in determining packaging strength, durability, and resistance. OJENILI provides specialized consulting to help you choose the best material based on product needs, transportation conditions, and storage requirements. This process includes evaluating longevity, weight, and environmental compatibility to ensure the final packaging delivers the best performance.

Printing and Quality Control Stages in Laminated Carton Production

In laminated carton production, the printing and quality control process is of high importance. These stages ensure that the produced cartons are not only visually beautiful and attractive but also perform their protective and functional roles well. Pre-printing stages include graphic design and print file preparation. In this stage, design and production teams create a unique and functional design by examining customer needs and product characteristics.

Quality control is performed in two stages, both during and after printing. During printing, color quality, print clarity, and design consistency are continuously monitored. After printing is complete, the final quality of cartons is checked for resistance, print accuracy, and color uniformity to ensure all produced cartons meet customer and industry standards.

Flexo Printing up to 4 Colors Simultaneously

One of the advanced technologies used in laminated carton printing is flexo printing. This method provides the ability to print multiple colors simultaneously and is therefore very popular. Flexo printing is especially suitable for die-cut cartons and export cartons that require colorful and attractive printing.

The advantages of this method include high printing speed, lower costs in large print runs, and excellent quality in printing complex colors. Flexo printing not only helps enhance the visual appeal of packaging but is also a suitable choice for packaging that requires transparency and color precision.

Sheet Manufacturing and Production of Custom Packaging Sheets

Sheet manufacturing and cardboard sheet selection is one of the main stages in laminated cardboard production. Selecting high-quality sheets and manufacturing with high precision directly impacts packaging strength and durability. Packaging cardboard sheets are usually made of multiple layers, whose composition is determined based on the product type, product weight, and transportation conditions. Proper raw material selection for sheet production ensures that cartons do not get damaged or deformed during transportation.

- Layer Structure: Packaging sheets are typically made of multiple layers. The combination of these layers is determined based on product needs, including weight, dimensions, and transportation conditions.

- Sheet Customization: In the sheet manufacturing process, complete customization of sheets is possible based on product type and customer needs. This ensures precise packaging suitability for the specific product and its conditions.

- Transportation Resistance: Selecting the right raw materials and manufacturing high-quality sheets guarantees that packaging will not be damaged or deformed during transportation.

- Use of New Technologies: The OJENILI team uses the latest technologies in producing three-layer and five-layer sheets to improve final product quality in addition to high strength.

- Product and Brand Image Preservation: High-quality packaging not only protects the product but can also improve brand image and play a key role in product differentiation.

Logistics and Laminated Cardboard Shipping

In the production and delivery process of laminated cardboard, logistics and shipping play a vital role. After carton production, the OJENILI team carefully performs packaging and shipping stages to ensure that products reach customers on time and with the highest quality level.

- Transportation Management: By using advanced logistics systems, OJENILI ensures that produced cartons reach customers in different parts of the country in the shortest possible time.

- Principled Packaging: Each order is packaged securely and robustly to prevent damage to cartons during transportation.

- Order Tracking: Customers can track their orders online in real-time and stay informed about the delivery process.

- Product Integrity Guarantee: OJENILI commits to delivering products safely and without defects to the final destination, and precise quality control is performed throughout all transportation stages.

Why Choose Us for Packaging Cardboard Production?

Choosing a reliable manufacturer for packaging cartons is crucial to your product's final quality. At OJENILI, we focus on quality, innovation, and attention to detail, providing services beyond expectations.

- Experience and Expertise: With years of experience in the packaging industry, our team is familiar with various simple, die-cut, and export cartons and offers the best packaging solutions for your needs.

- Unparalleled Quality: OJENILI uses premium raw materials and modern technologies to produce high-quality cartons. Flexo printing up to 4 colors and the ability to print directly on cardboard with quality close to offset are among our additional advantages.

- Specialized Consultation: We will help you choose the best material and design for packaging cartons to ensure your products look their best in the market.

- Precise Quality Control: All production and printing stages undergo precise quality control to ensure cartons reach you in the best possible condition.

- Comprehensive Services: From initial design and prototyping to logistics and shipping, OJENILI accompanies you at every stage, providing complete and comprehensive services.

Consultation and Laminated Cardboard Order Registration

At OJENILI, the order registration process is easy and hassle-free. You can consult and place orders online through our website.

- Free Consultation: Our specialized team is ready to provide free consultation regarding the selection of the best structure, material, and design for your product packaging. To get more information and receive guidance, simply contact us or send your request through our website.

- Easy Order Registration: After receiving consultation, you can register your order online. Our system is designed so that you can manage and track your orders with just a few simple clicks.

- Comprehensive Support: From the moment of order registration to final product delivery, our support team is beside you to answer your questions and needs.

At OJENILI, we offer our customers a different experience of printing and packaging. By utilizing advanced technologies, high-quality materials, and a creative design team, we can provide the best solutions for all your packaging needs, from fast food boxes to export and health packaging. Our packaging products not only preserve the quality and durability of your products but also help enhance your brand.

If you are looking for cardboard and laminated box printing with the highest quality and most competitive prices, contact our team at OJENILI right now. We provide free consultation and stand by you throughout all stages from design to printing and shipping to create the best experience for you and your customers.