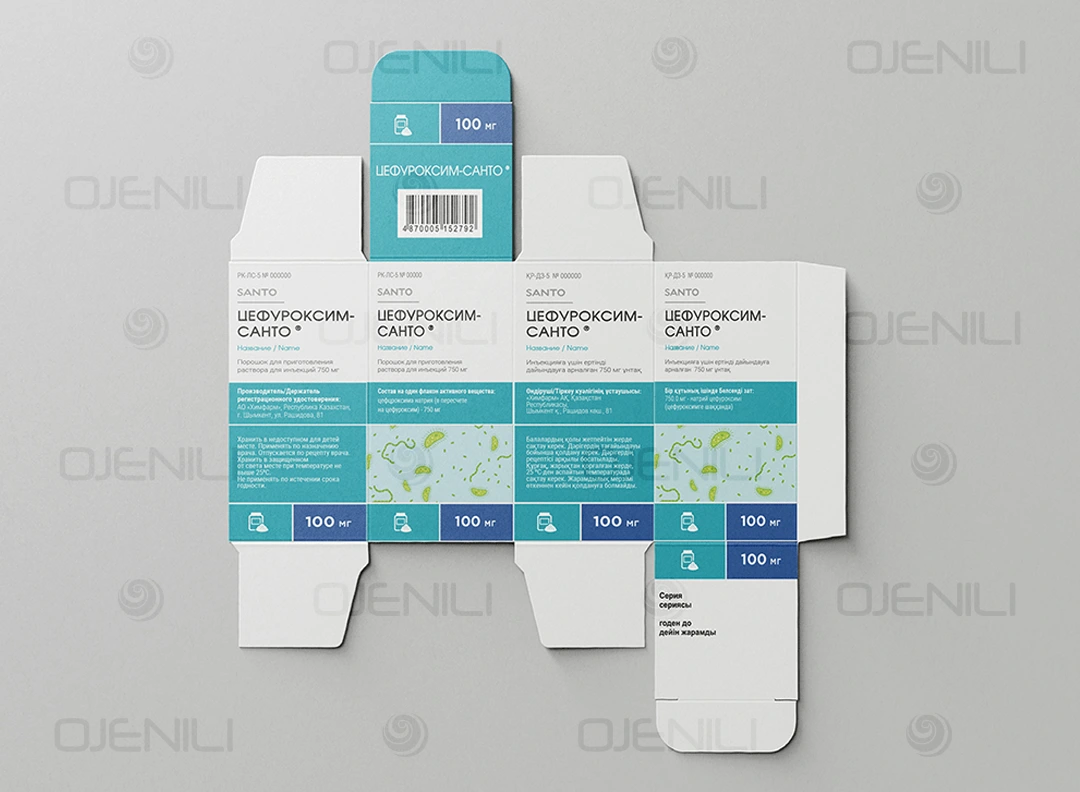

Printing Various Types of Medicine Boxes

Design and printing of medicine boxes is one of the most important parts of drug packaging that plays a vital role in protecting internal contents and extending their useful life. Medicine boxes, in addition to physical protection of medicines against external damages such as impact, light, and moisture, also have the task of transferring important information such as usage method, expiration date, ingredients, and safety warnings. Printing medicine boxes with appropriate information and details (such as drug storage method and conditions, usage instructions, etc.) can help prevent usage errors and ensure better drug preservation. As a result, medicine box design and printing must comply with health and safety standards to preserve the quality and authenticity of medicines. These boxes, in addition to drug packaging, have various other applications such as food packaging, cable boxes, toy boxes, lamp boxes, toothpaste boxes, cosmetic boxes, and more.

Medicine Box Materials

Selecting the material for medicine boxes is one of the key factors in producing hygienic and safe packaging for pharmaceutical products. The cardboards used in medicine boxes must be resistant, hygienic, and suitable for protecting medicines against environmental factors such as moisture, light, and pollution. The most common raw material in medicine box production is Inderboard cardboard.

Inderboard cardboard, due to its smooth and white surface, is very suitable for printing medicine boxes and allows important information such as usage instructions, production and expiration dates to be clearly displayed. This type of cardboard has high resistance to moisture and impact, which helps maintain the quality of the medicine. Inderboard cardboard is compatible with international hygiene standards and is considered an ideal option for hygienic pharmaceutical packaging that requires adherence to safety and health principles.

Overall, selecting appropriate material and structure for medicine boxes directly affects product quality and shelf life and can prevent physical and chemical damages.

Types of Medicine Box Lids

There are various types and diverse structures for medicine boxes, but more than 90% of them are produced with similar structures to best meet packaging and product protection needs. Each type of medicine box has its specific characteristics and is chosen based on the type of product, storage conditions, and transportation. Here we will introduce the types of medicine boxes and their structures:

Locked Bottom Box | Lock Bottom

Locked Bottom Box or Lock Bottom Box, known in Latin as Lock Bottom Box, has a locking system at the bottom that increases packaging strength and safety. Locked bottom boxes are ideal for heavier pharmaceutical products or products that require more protection. Key features of these boxes include:

- High strength against pressure

- Suitable for liquid medicines or syrups

- Possibility of offset printing for high-quality designs

Two-Piece Box

Two-piece box, or base and lid box, is typically used for packaging luxury pharmaceutical products or products that require more protection. These boxes have a base section and a separate lid that keep the packaging secure and sturdy. Features of these boxes include:

- High resistance to impact

- Suitable for sensitive products such as medical equipment, ampoules, etc.

- Capability of custom printing of medicine boxes with personalized designs

Blister Packaging

Printing Blister Packaging is suitable for packaging pharmaceutical, cosmetic, and hygiene products individually or in multiple units. Blister packaging for multiple units is usually used for tablets and capsules and is made of transparent plastic with a cardboard backing. Features of this packaging:

- Complete protection of the medicine

- Suitable for various types of medicines and hygiene products

- Ability to print information clearly and legibly on the cardboard